Huashida petrol, gaz, petrokimya ve su endüstrilerinde boru hattı korozyon koruması için tasarlanmış PE soğuk uygulamalı antikorozyon bant üretim makineleri üretmektedir.

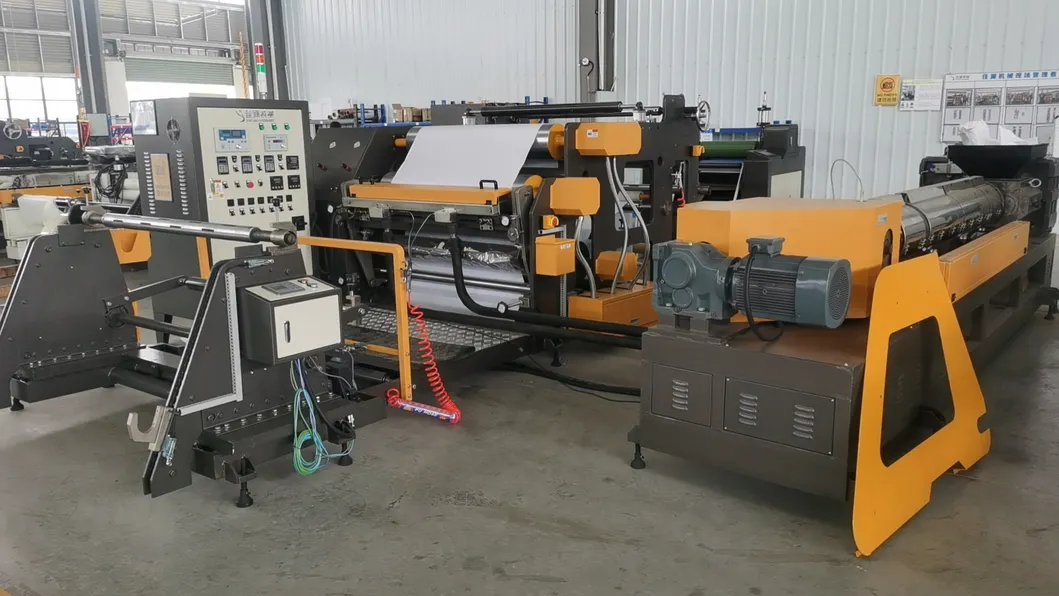

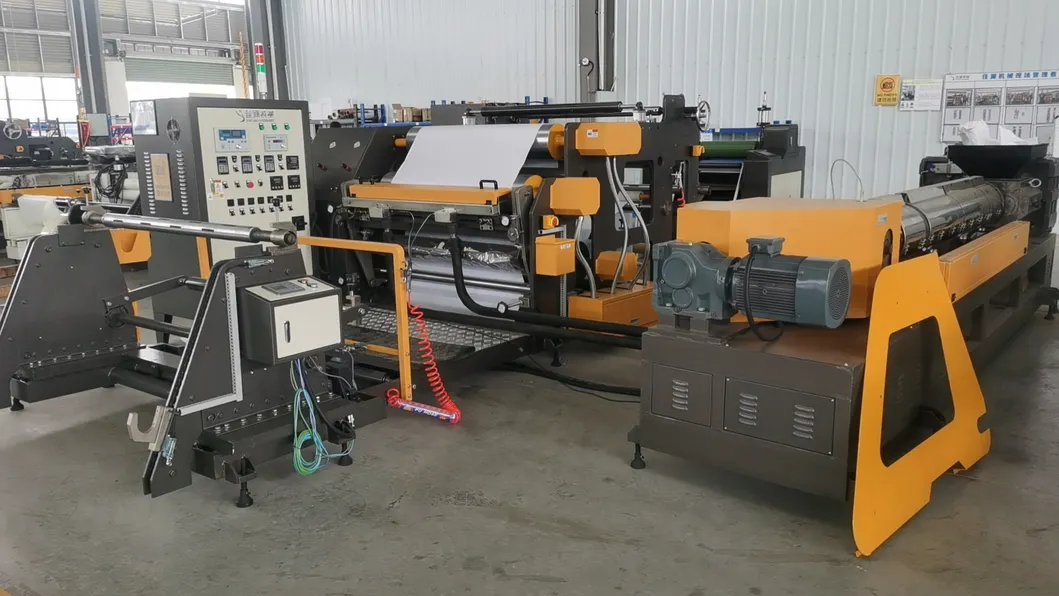

Üretim hattı, yüksek performanslı PE boru hattı sarma bandı üretimi için eksiksiz bir çözüm sunan PE film ekstrüzyonu, butil kauçuk yapışkan kaplama ve otomatik dilimlemeyi entegre eder.

Teknolojik süreçler

Soğuk Uygulamalı Antikorozyon Bant Üretim Süreci

Soğuk uygulamalı antikorozyon bandın üretim süreci genellikle üç ana aşamadan oluşur: baz film ekstrüzyonu, yapışkan kaplama ve dilme ve paketleme. Her adım, ürünün tekdüzeliğini, yapışma performansını ve uzun süreli dayanıklılığını sağlamak için tasarlanmıştır.

1. Baz Film Ekstrüzyonu

Ham Madde Hazırlığı:

Baz film için birincil malzeme olarak polietilen (PE) granüller kullanılır. Ham madde, saflığı ve tutarlı kaliteyi sağlamak için dikkatle hazırlanır.

Ekstrüzyon Şekillendirme:

PE malzeme ekstrüderde ısıtılır ve eritilir, daha sonra kararlı bir yapıya sahip sürekli bir film üretmek için bir kalıptan ekstrüde edilir.

Soğutma ve Kalibrasyon:

Erimiş film, düzgün kalınlık ve pürüzsüz yüzey özellikleri elde etmek için katılaşan ve şekillendiren soğutma silindirlerinden geçirilir.

2. Yapışkan Kaplama

Yapışkan Hazırlama:

Optimum yapışma performansı için gerekli viskozite, yapışkanlık ve kararlılığı elde etmek üzere butil kauçuk bazlı yapıştırıcılar bileştirilir.

Kaplama Uygulaması:

Hazırlanan yapışkan, tutarlı ve düzgün bir yapışkan tabakası oluşturarak, hassas kaplama ekipmanı kullanılarak PE baz filmin bir veya her iki tarafına eşit olarak uygulanır.

3. Dilme ve Paketleme

Dilme Kurulumu:

Kaplamalı film rulosu dilme makinesine yüklenir ve kesme parametreleri istenen bant genişliği özelliklerine göre ayarlanır.

Dilme İşlemi:

Geniş yapışkan kaplı film, temiz kenarlar ve doğru boyutlar sağlayarak soğuk uygulamalı bandın dar rulolarına dilimlenir.

Sarma ve Son Paketleme:

Bitmiş bantlar rulolar halinde sarılır, dikkatlice kontrol edilir, paketlenir ve depolama veya sevkiyata hazırlanır.

Ürün Parametreleri

PE baz dosya ekstrüzyon hattı

|

Ekipman Adı |

Miktar |

| 1 |

Vakum otomatik besleyici |

1 |

| 2 |

Hazne kurutucu |

1 |

| 3 |

SJ-75X30 ekstrüder |

1 |

| 4 |

Hidrolik elek değiştirici |

1 |

| 5 |

Kalıp kafası kalıbı tipi 1000 |

1 |

| 6 |

Çok silindirli bant döküm makinesi |

1 |

| 7 |

Sarma makinesi |

1 |

| 8 |

PLC bilgisayar kontrol sistemi |

1 |

Yapışkan kaplama makinesi

| No. |

Ekipman Adı |

Miktar |

| 1 |

Çerçeve |

1 birim |

| 2 |

200N·M Manyetik toz freni + Silikon çubuk 1300mm korona işlemcisi ile |

1 birim |

| 3 |

100N·M Manyetik toz freni |

1 birim |

| 4 |

100N·M manyetik toz debriyajı |

2 birim |

| 5 |

200N·M manyetik toz debriyajı |

1 birim |

| 6 |

Vida |

1 birim |

| 7 |

Zorlamalı besleme cihazı |

1 birim |

| 8 |

Sabit basınç sistemi |

1 birim |

| 9 |

Yapışkan dağıtım borusu |

1 birim |

| 10 |

Sarma makinesi |

1 birim |

| 11 |

Çözme makinesi |

2 birim |

| 12 |

Kaplama bileşik ekipmanı |

1 birim |

| 13 |

Ana motor frekans konvertörü |

1 birim |

| 14 |

Ekstrüder frekans konvertörü |

1 birim |

| 15 |

Termal anahtar |

1 birim |

| 16 |

PLC |

1 birim |

Avantajlarımız

-Gelişmiş teknolojiyi benimseyin

-Kararlı çalışma

-Yüksek otomasyon derecesi, işçilik maliyetlerinden tasarruf

-İyi kalite, uluslararası standardı karşılar

-Tamamlanmış üretim çözümü sağlayın: tasarım, kurulum, devreye alma, eğitim

-Dünyadan 389 set üretim deneyimini paylaşın

-9 profesyonel kıdemli mühendise sahip olmak

-Çin'de üst düzey plastik makine ekipmanı uzmanı iş istasyonuna sahip olmak

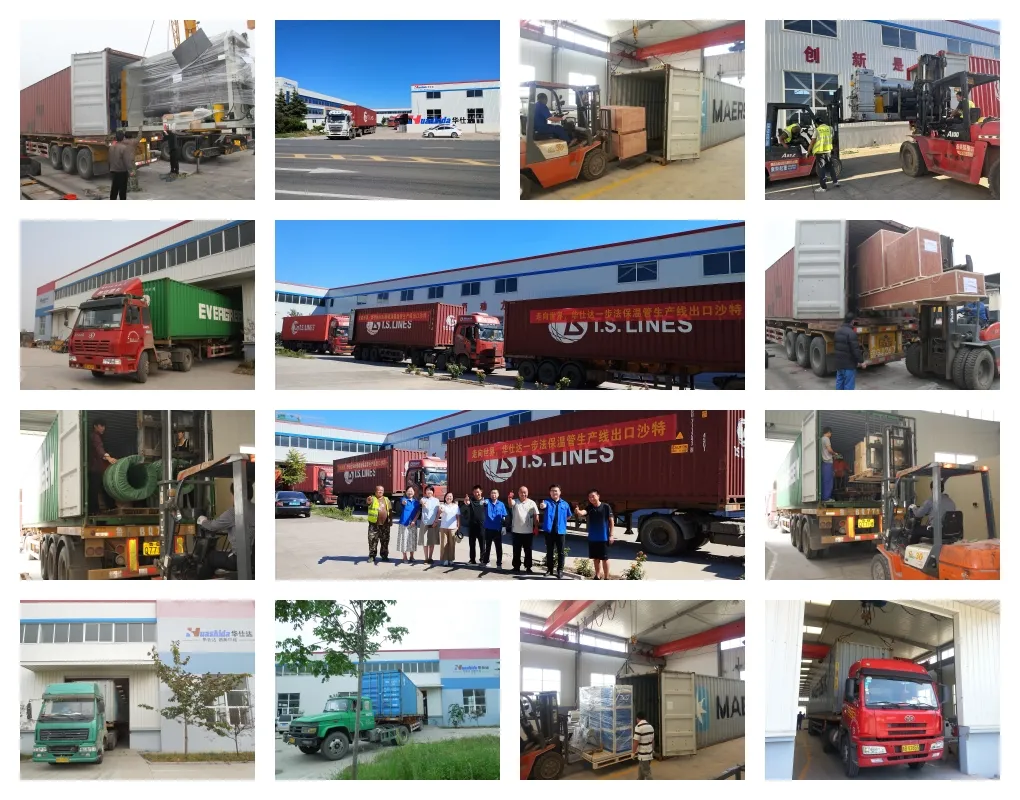

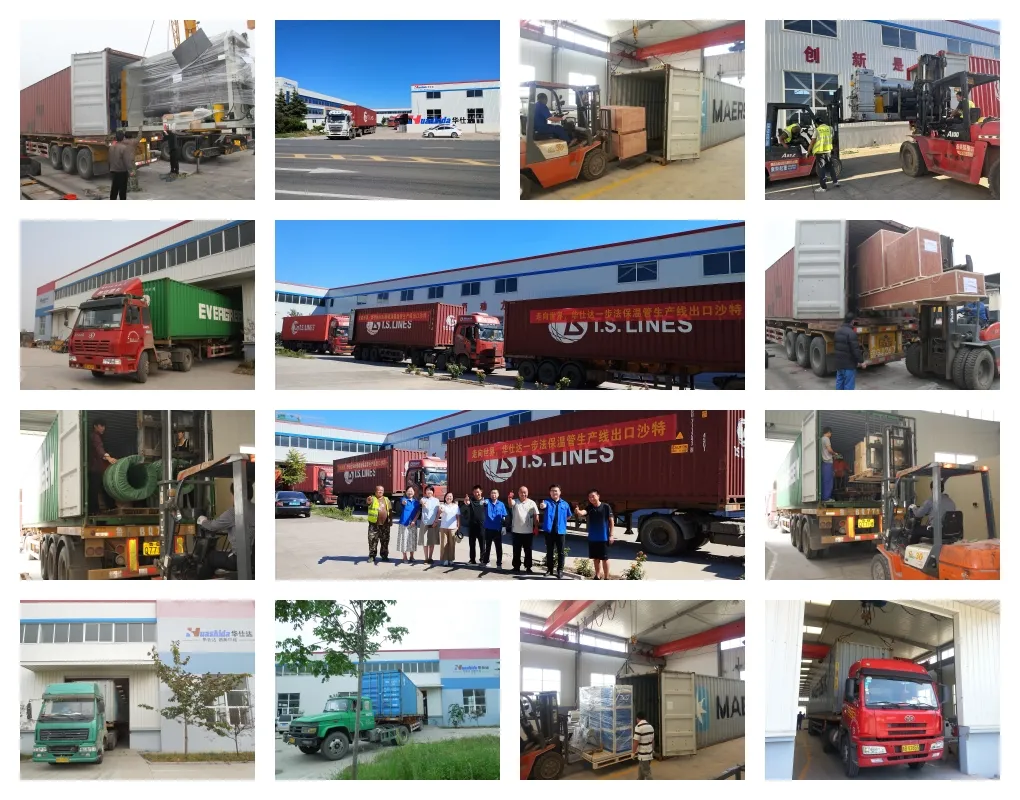

Müşteri vakaları

Şirket Profili

Qingdao Huashida Machinery Co., LTD, seri üreticisidirs plastik boru makineleri, belediye boru makineleri, boru izolasyonu&antikorozyon makineleri, ve boru birleştirme&antikorozyon malzemeleri, 21 yıllık üretim tecrübesi ile.

Ana ürünlerimiz şunlardır:

1. Ön yalıtımlı boru Üretim Hattı için HDPE ceket borusu (110-2000mm)

2. Sert ön yalıtımlı boru Üretim Hattı

3. Esnek ön yalıtımlı boru (PERT) üretim hattı

4. Çelik boru FBE/2LPE/3LPE korozyon önleyici kaplama hattı

5. Çelik boru pas sökme hattı

6. PE basınç boru/Su Gazı besleme borusu üretim hattı

6. PP/PE plastik levha/tabaka/jeozar üretim hattı

7. NBR PVC Thermal izolasyon borusu/levha üretim hattı

8. Boru hattı korozyon önleyici malzemeler ve aletler: ısı büzüşmeli bağlantı kaplama manşonu, elektrofüzyon kaynaklanabilir bağlantı manşonu, taşınabilir kaynak tabancası (ekstrüder), PE PP kaynak çubuğu.

400'den fazla denizaşırı müşteriyle çalışıyoruz ve ürünlerimizi Kazakistan, Özbekistan, İran, Türkiye, Rusya, Nijerya ve diğer ülkelere ihraç ediyoruz.

Ekibimiz

Teslimat

Sergi

Sertifikalar

Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!  Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!