3PE anti-corrosion coating is that the steel pipe is protected by three layers to prolong the life of service from 5-10years to 50-100years.

First layer is Fusion bonded epoxy layer (FBE> 100µm), the second layer is adhesive (AD) 170 ~ 250µm, and the third layer is polyethylene (PE) stripe 2.5 ~ 3.7mm.

3PE steel coating pipe has the features of high mechanical strength, excellent electrical insulation performance, Process accuracy and environmental friendliness.

Application

3PE (3-layer polyethylene) coated pipes are high-performance anti-corrosion steel pipes widely used in demanding environments for long-distance transportation projects. The three-layer structure (fusion-bonded epoxy powder, adhesive layer, and polyethylene outer sleeve) provides superior corrosion resistance, mechanical protection, and durability. Key application areas include:

1. Oil & Gas Transportation

-

Long-distance pipelines: Used for high-pressure transportation of crude oil, natural gas, and refined petroleum products, resistant to soil corrosion and chemical erosion.

-

Offshore engineering: Suitable for subsea pipelines, withstanding saltwater spray and high humidity to extend service life.

2. Urban Pipeline Networks

-

Gas pipelines: Excellent anti-permeability ensures safe gas delivery.

-

Water supply systems: Prevents water contamination, ideal for municipal drinking water and sewage pipelines.

3. Chemical & Industrial Applications

-

Chemical fluid transportation: Resistant to acids, alkalis, salts, and other corrosive media, widely used in chemical plants and refineries.

-

Slurry pipelines: Exceptional abrasion resistance for mining and mineral slurry transport.

4. Harsh Environments

-

Extreme cold/hot regions: The PE layer performs stably in temperatures ranging from -40°C to 80°C.

-

Saline-alkali/swamp areas: Triple-layer protection effectively resists electrochemical and microbial corrosion.

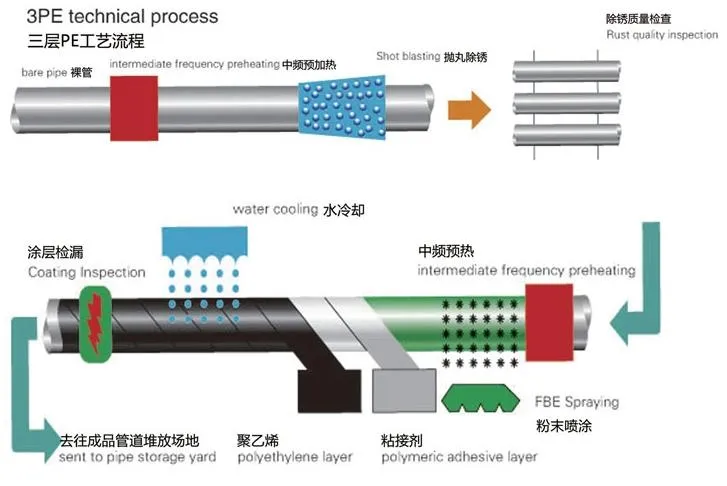

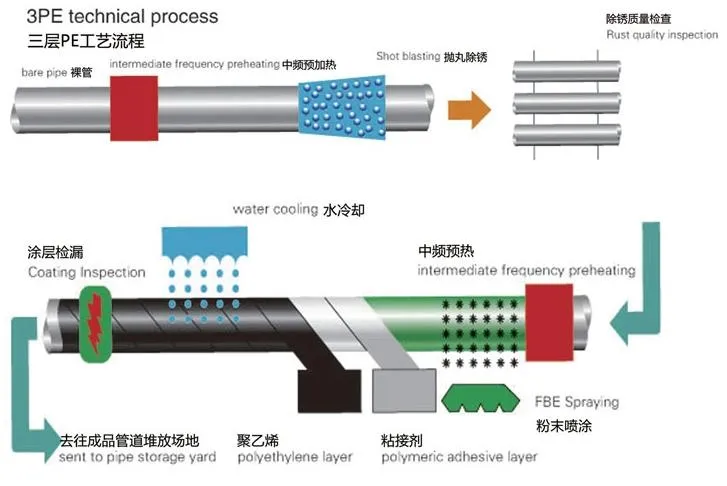

Technological flow

Upload pipes→pipes conveyor→rust removal→intermediate frequency heating→Epoxy powder coating→Middle layer &polyethylene stripe winding→water cooling→pipes conveyor→ pipe chamfer→unload pipes

Blasting machinery

steel pipe conveyor

FBE Coating machinery

PE/PP layer wrap extruder line

Product Parameters

Main Equipment of 3PE anti-corrosion coating processing

| No. |

Name |

Set |

| A. Derusting Equipment |

| 1 |

Pipe-conveying Equipment |

1 |

| 2 |

Shot Blast Cleaning Machine |

1 |

| 3 |

Cyclone Dust Collector |

1 |

| 4 |

Pulse dust collector |

1 |

| 5 |

Centrifugal exhaust fan |

1 |

| 6 |

Rust removal equipment PLC |

1 |

| B. Coating equipment |

| 1 |

Coating transfer equipment |

1 |

| 2 |

IF heating device |

1 |

| 3 |

Powder spraying device |

1 |

| 4 |

Automatic loading dryer |

2 |

| 5 |

SJ-65/30 Extruder |

1 |

| 6 |

SJ-180/30 Extruder |

1 |

| 7 |

Hot melt adhesive extruder die |

1 |

| 8 |

PE sheet extruder head mold |

1 |

| 9 |

Hot melt adhesive/PE sheet coating device |

1 |

| 10 |

Environmental Protection Ventilation equipment |

1 |

| 11 |

Cooling Spray equipment |

1 |

| C.Platform Equipment |

| 1 |

Steel pipe platform |

1 |

| 2 |

Post-rust removal transition platform |

1 |

| 3 |

Product tube storage platform |

1 |

| 4 |

Hydraulic Equipment |

3 |

| D.Groove Equipment |

| 1 |

PE Beveling Machine |

2 |

| 2 |

Hydraulic Lifting and Turning Machinery |

1 |

| 3 |

Hydraulic Equipment |

1 |

| 4 |

PLC |

1 |

| E.Compressed air Equipment |

| 1 |

Screw Air Compressor |

1 |

| 2 |

Cold dry machine |

1 |

| 3 |

Precision filters |

3 |

| 4 |

Gas tanks |

1 |

Company Profile

Qingdao Huashida Machinery Co., Ltd was established in 2003. Since its

inception, Huashida has focused on plastic polyurethane insulation pipe

production line, 3PE anti-corrosion pipe production line, large diameter

underground pipe production line and plastic pipe joints for 20 years.

We always attach great importance to research and development,

collaborating closely with Tsinghua University, Beijing University of

chemical technology, South China university of technology and scientific

research institutions. by absorbing advanced technology home and

abroad, we now rank one of the top 3 manufacturers in the industry in

China.

Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!  Mesajınız 20-3.000 karakter arasında olmalıdır!

Mesajınız 20-3.000 karakter arasında olmalıdır! Lütfen emailinizi kontrol edin!

Lütfen emailinizi kontrol edin!